Optimise truck payload measurement with AI-driven 3D scanning.

Tolveet employs patented multisensory 3D scanning and artificial intelligence for real-time, in-motion, and static scanning. Receive accurate data on cargo volume, material classification, and аудит повного завантаження в одній компактній системі.

Update your truck operational workflows with швидке повернення інвестицій та мінімальний ризик.

Замовте демо-версію в реальному часіЗастарілі об'ємно-лазерні сканери використання одноплощинного 2-D LiDAR із рухомою оптикою; точне визначення крапель пилу, дощу, відблисків і вібрації. Tolveet є повністю тривимірним і мультисенсорним, точним при змінних швидкостях і умовах на майданчику, з повнішими даними й без рухомих частин.

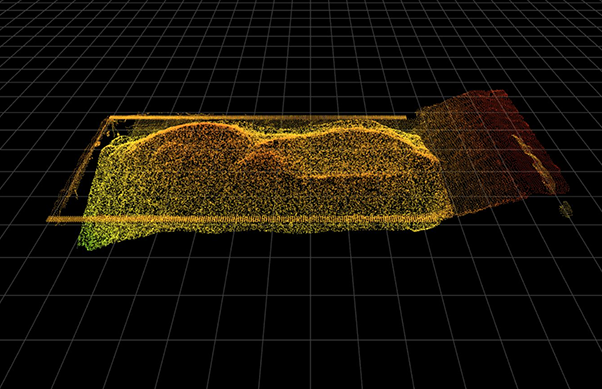

How it works: Real-time AI-powered 3D scanning

Durable fuse module weighing 11 kg, pole-mounted LiDAR + стереокамери on the device. Edge AI constructs a labelled 3D mesh of each pass in real-time, calculates the actual measured volume of cargo (including cold start estimation without an empty bucket), and classifies material, ensuring accuracy independent of humidity, without moving parts or external PCs.

Thorough cargo audit with 3D models, actual volume, and autonomous truck identification, secured on-device and synchronized with our reports/API. Reliability in all environmental conditions.

Відмінності

| Сканер об'єму вантажу Tolveet | Застарілі об'ємно-лазерні сканери | |

|---|---|---|

| Мультисенсорне резервування | Додаткові 3D-сенсори працюють у тандемі; коли сильний пил, дощ, відблиски або сутінки заважають одному, інший заповнює прогалини. | Одноплощинний 2-D LiDAR Productivity rapidly declines in fog, during dust emissions, with reflective loads, or in low-light conditions; operators often slow down the vehicles. |

| Режим сканування | У русі та статиці в одному пристрої (обирається програмно): In-Motion = проїзд; Static = коротка зупинка для максимальної точності. | Однорежимний for installation; mode switching requires new equipment and calibration. |

| Розміри | 621 × 248 × 210 мм, 11 кг. Mounted on a lamp post or an existing gantry bracket. | Laser head weighing 40-60 kg, reinforced structure, and concrete base. |

| Загальна вартість володіння | До У 10 разів менші капітальні витратиwithout an external computer, without moving parts, includes OTA updates. | $45,000 - $110,000 per belt, plus an industrial PC and regular maintenance of the movable optics. |

| Глибина даних | Маркована 3-D сітка (вантажівка, корисне навантаження, перевезення), класифікація матеріалів, прив'язка RFID/QR/ANPR та постійні оновлення комп'ютерного зору, включаючи автоматичне вимірювання об'єму вантажу. | Only volumetric profiling; traceability and classification are optional add-ons or simply unavailable. |

| Точність | ± 2% (LVS model) or ± 1% (LVS-F model) at normal flow rate. | Заявлена похибка ± 1-3 %, але досяжна лише тоді, коли вантажівки проходять під щойно очищеною лазерною головкою; пил, вібрація чи звичайна швидкість руху швидко знижують точність. |

| Масштабованість та оновлення | Перший підхід зі штучним інтелектом Моделі навчаються на кожному скануванні та оновлюються в режимі реального часу, залишаючи можливість для майбутніх удосконалень комп'ютерного зору на тому ж обладнанні. | 2D LiDAR hardware design; significant improvements typically require new sensors or replacement of the entire system. |