Memodernisasi Pengukuran Beban Truk dengan AI dan Penginderaan 3D

Tolveet memanfaatkan penginderaan 3D multi-sensor dan AI tepi eksklusif untuk pemindaian real-time, bergerak & statis. Dapatkan volume muatan yang akurat, klasifikasi material, dan audit beban penuh dalam satu sistem yang ringkas.

Tingkatkan alur kerja muatan truk Anda dengan ROI yang lebih cepat dan risiko minimal.

Pesan Demo LangsungPemindai laser volumetrik lawas menggunakan LiDAR 2-D bidang tunggal dengan optik bergerak; presisi dalam kondisi debu, hujan, silau, dan getaran. Tolveet sepenuhnya 3-D dan multi-sensor, akurat pada kecepatan serta kondisi lokasi yang bervariasi, dengan data lebih mendalam dan tanpa bagian bergerak.

Bagaimana cara kerjanya: Penginderaan 3D AI Waktu Nyata

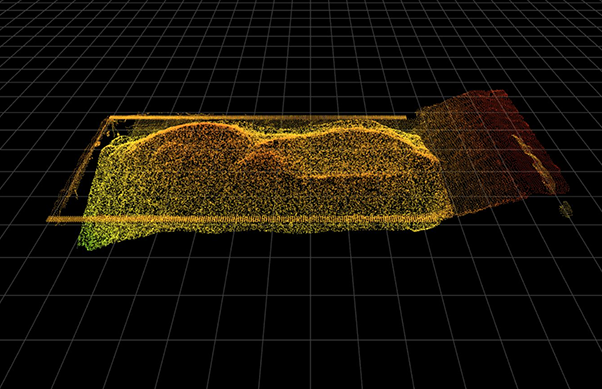

Modul sekering yang kokoh dengan berat 11 kg dipasang di tiang. LiDAR + kamera stereo di perangkat. Edge AI membangun mesh 3D berlabel secara real-time dari setiap lintasan, menghitung volume beban aktual yang terukur (termasuk estimasi cold-start tanpa ember kosong), dan mengklasifikasikan material, memberikan akurasi tanpa tergantung pada kelembapan, tanpa komponen bergerak atau PC eksternal.

Lakukan audit muatan secara menyeluruh dengan model 3D, volume aktual, dan identifikasi truk secara otomatis, yang diamankan di perangkat dan disinkronkan ke laporan/API kami. Dapat diandalkan dalam berbagai kondisi lingkungan.

Perbedaan

| Pemindai Volume Beban Tolveet | Pemindai Laser Volumetrik Lawas | |

|---|---|---|

| Redundansi multi-sensor | Sensor 3D yang saling melengkapi bekerja bersama; ketika debu tebal, hujan, cahaya silau, atau malam hari menghalangi satu sensor, sensor lainnya akan mengisi kekosongan. | LiDAR 2-D bidang tunggal Performa cepat menurun dalam kabut, angin kencang, beban reflektif, atau cahaya redup; operator sering memperlambat kendaraan. |

| Mode Pemindaian | Dalam Gerakan & Statis dalam satu perangkat (dapat dipilih melalui perangkat lunak): In-Motion = bergerak terus; Statis = jeda sebentar untuk presisi maksimal. | Mode tunggal per instalasi; peralihan mode memerlukan perangkat keras baru & kalibrasi ulang. |

| Dimensi | 621 × 248 × 210 mm, 11 kg. Dipasang pada tiang lampu atau gantry yang ada. | Kepala laser 40-60 kg dengan struktur diperkuat dan dasar beton. |

| Total Biaya Kepemilikan | Hingga 10× belanja modal lebih rendahtidak memerlukan PC eksternal, tanpa komponen bergerak, mencakup pembaruan OTA. | USD 45 ribu-110 ribu per jalur, ditambah PC industri dan perawatan rutin untuk optik bergerak. |

| Kedalaman Data | Jaringan 3-D berlabel (truk, muatan, carry-back), klasifikasi material, koneksi RFID/QR/ANPR, dan peningkatan visi komputer, termasuk pengukuran volume muatan otomatis. | Hanya profil volume; ketertelusuran dan klasifikasi adalah tambahan opsional atau mungkin tidak tersedia. |

| Akurasi | ± 2% (Model LVS) atau ± 1% (Model LVS-F) pada kecepatan operasional jalan angkut normal. | Diumumkan akurasi ± 1-3%, tetapi ini hanya dapat dicapai ketika truk berjalan pelan di bawah kepala laser yang baru dibersihkan; debu, getaran, atau kecepatan normal perjalanan dengan cepat menurunkan presisi. |

| Skalabilitas & Peningkatan | Pendekatan yang mengutamakan AI Model terus belajar dari setiap pemindaian dan diperbarui melalui pembaruan udara, sehingga menyediakan ruang untuk peningkatan visi komputer di masa depan pada perangkat keras yang sama. | Desain LiDAR 2D terkait perangkat keras; peningkatan signifikan biasanya memerlukan sensor baru atau penggantian sistem seluruhnya. |