Modernize Truck‑Load Measurement with AI‑Powered 3‑D Sensing

Tolveet uses proprietary multi-sensor 3D sensing and edge AI for real-time, in-motion scanning. Get accurate load volume, material classification, and full load auditing in one compact system.

Upgrade your truck-load workflows with faster ROI and minimal risk.

Book a Live DemoLegacy volumetric‑laser scanners use a single moving beam and heavy optics; accuracy drops in dust, rain or vibration and trucks must slow to crawl. Tolveet’s AI multi‑sensor scanner maintains precision at full speed and delivers richer data with no moving parts.

Our compact 11 kg scanner mounts on a standard pole with no external PC required. It streams labelled real‑time 3‑D meshes, automatic load volumes and moisture‑independent accuracy at a fraction of legacy cost.

Every scan is processed on‑device, then pushed to secure APIs for ERP, dispatch or ticketing systems.

How It Works: Real‑Time AI‑Powered 3‑D Sensing

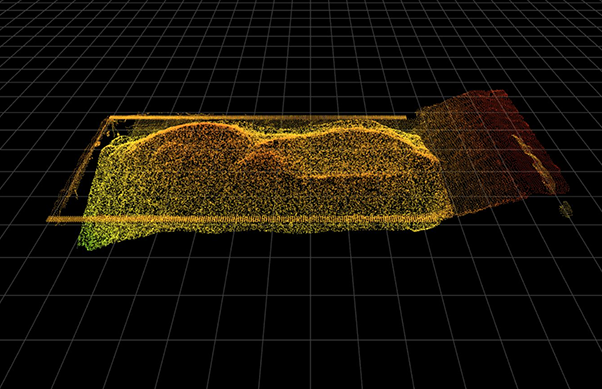

A rugged 3‑D sensing module blends complementary depth channels on‑device, delivering a ready‑to‑use 3‑D load model with volume and material labels. Data syncs automatically to your cloud dashboard for real‑time alerts and audit‑grade records, even through dust, rain or glare.

Differences

| Tolveet Load Volume Scanner | Legacy Volumetric‑Laser Scanners | |

|---|---|---|

| Multi‑sensor redundancy | Complementary depth channels work in tandem; when heavy dust, rain, glare or nightfall hinders one, the other fills the gaps. | Single‑plane 2‑D LiDAR. Performance falls off rapidly in fog, blowing fines, reflective loads or low‑light conditions; operators often slow vehicles. |

| Dimensions | 621 × 248 × 210 mm, 11 kg. Mounts on a light pole or existing gantry. | 40‑60 kg laser head plus a reinforced structure and concrete base. |

| Total Cost of Ownership | Up to 10× lower CapEx; no external PC, no moving parts, OTA updates included. | US $45k‑110k per lane plus an industrial PC and regular maintenance on moving optics. |

| Data Depth | Labelled 3‑D mesh (truck, payload, carry‑back), material classification, RFID/QR/ANPR linking and ongoing computer‑vision upgrades, including automatic load volume measurement. | Volume profile only; traceability and classification are optional add‑ons or simply unavailable. |

| Accuracy | ± 2 % (Model LVS) or < ± 1 % (Model LVS-F) at normal haul‑road speed. | Advertised ± 1–3 %, but reachable only when trucks crawl under a freshly cleaned laser head; dust, vibration or normal travel speed quickly degrade precision. |

| Scalability & Upgrades | AI‑first approach: models keep learning from every scan and roll out via over‑the‑air updates, leaving headroom for future computer‑vision enhancements on the same hardware. | Hardware‑bound 2‑D LiDAR design; meaningful improvements usually require new sensors or an entire system replacement. |